Industrial AI is revolutionizing factories by analyzing large volumes of sensor and machine data to uncover patterns,...

Year: 2025

Vibration monitoring is one of the most effective methods for detecting mechanical issues in industrial equipment. It...

Predictive maintenance uses real-time and historical industrial data to detect early signs of equipment failure. Instead of...

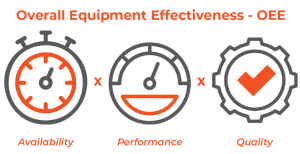

Overall Equipment Effectiveness (OEE) is one of the most important metrics in manufacturing. It measures how efficiently...

Energy is one of the largest operating costs in industrial facilities. With proper energy monitoring, factories can...

Real-time data is important, but historical data storage is what allows factories to analyze trends, optimize processes,...

In industrial data acquisition, collecting data is only half the job. A well-designed alarm system turns data...

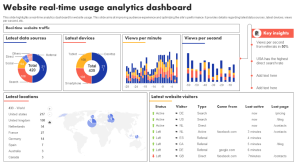

A real-time dashboard is one of the most powerful tools in industrial data acquisition. It transforms raw...

Edge computing is transforming how factories collect, process, and use industrial data. Instead of sending all raw...

Remote monitoring is no longer optional for modern factories. Connecting your industrial equipment to a web-based DAQ...