Overall Equipment Effectiveness (OEE) is one of the most important metrics in manufacturing. It measures how efficiently equipment is used and helps identify hidden losses in production.

1. What Is OEE?

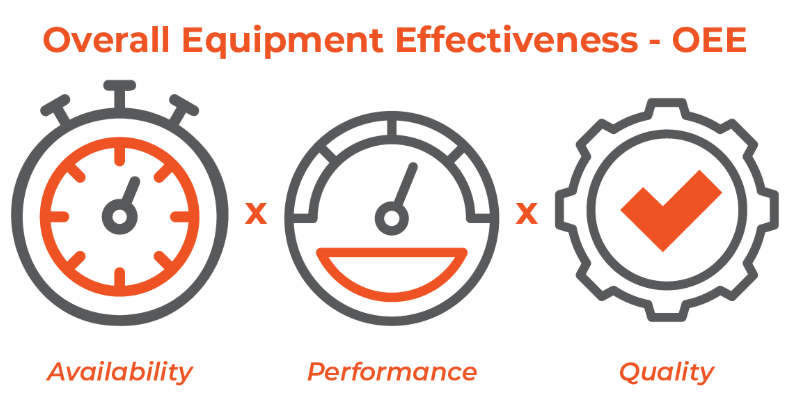

OEE is calculated using three factors:

- Availability — How often the machine is running

- Performance — How fast the machine operates compared to its ideal speed

- Quality — How many good products are produced

OEE = Availability × Performance × Quality

2. Why OEE Matters

A low OEE indicates:

- Unplanned downtime

- Slow cycles

- Frequent quality defects

Improving OEE directly increases output without buying new machines.

3. How Data Acquisition Enables OEE

An industrial DAQ system automatically collects:

- Machine run/stop signals

- Cycle times

- Production counts

- Reject counts

- Downtime reasons

This eliminates manual reporting and improves data accuracy.

4. Real-Time OEE Monitoring

With a web-based platform, teams can:

- View OEE in real time

- Compare shifts, lines, or machines

- Identify bottlenecks instantly

- Track improvement over time

Visual dashboards make OEE actionable, not just a report.

5. Benefits of Data-Driven OEE

- Increased production capacity

- Reduced downtime

- Better maintenance planning

- Improved product quality

- Higher return on existing assets

OEE turns industrial data into measurable operational improvement.