Predictive maintenance uses real-time and historical industrial data to detect early signs of equipment failure. Instead of reacting to breakdowns, factories can fix problems before they cause downtime.

1. What Is Predictive Maintenance?

Predictive maintenance analyzes data from:

- Vibration sensors

- Temperature sensors

- Current and power meters

- Runtime and cycle counters

The goal is to identify abnormal patterns that indicate wear or malfunction.

2. Why Predictive Maintenance Matters

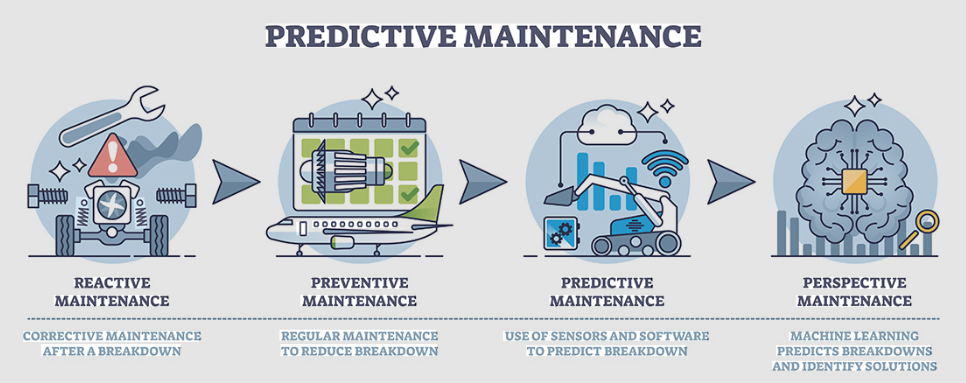

Traditional maintenance strategies are either:

- Reactive — fix after failure

- Preventive — service on a fixed schedule

Both waste time and money. Predictive maintenance:

- Reduces unplanned downtime

- Extends equipment lifespan

- Lowers maintenance costs

- Improves production reliability

3. Key Data Used for Prediction

Common indicators include:

- Rising vibration levels

- Increasing motor temperature

- Abnormal current consumption

- Frequent start/stop cycles

- Trend deviations over time

These signals often appear weeks before failure.

4. Role of DAQ and Edge Computing

Industrial DAQ systems and edge devices:

- Collect high-frequency sensor data

- Filter noise locally

- Calculate trends and thresholds

- Trigger early alarms

Only relevant insights are sent to the cloud.

5. From Monitoring to Prediction

With enough historical data, platforms can:

- Detect patterns

- Build baseline models

- Identify anomalies

- Support AI-based prediction

Predictive maintenance transforms maintenance from cost center to value creator.