Modbus RTU uses a simple register-based structure, but many engineers still get confused when integrating new sensors, meters, or PLCs. Understanding register types is essential for accurate data acquisition.

1. The Four Modbus Register Types

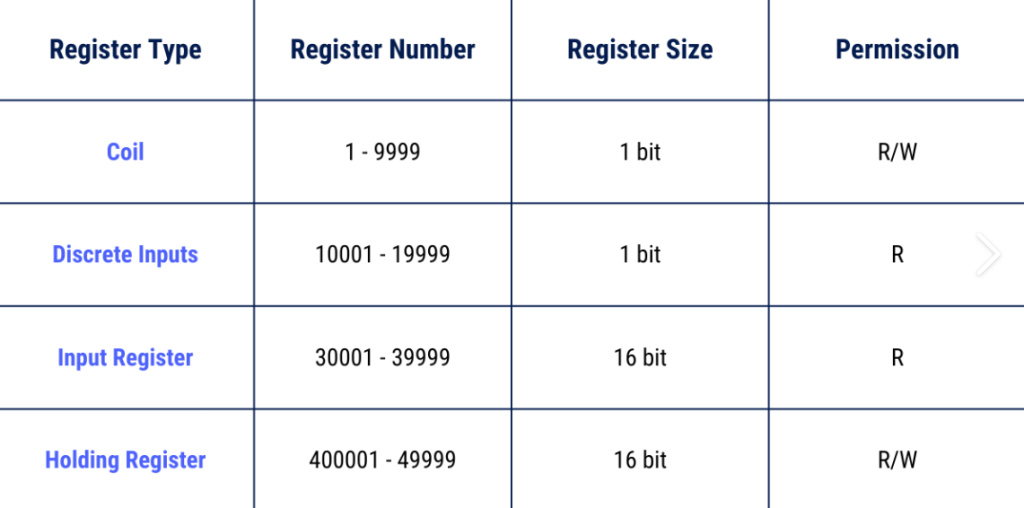

Modbus defines four primary data areas:

- Coils (00001–09999)

- Read/Write

- Digital outputs (ON/OFF)

- Discrete Inputs (10001–19999)

- Read-only

- Digital inputs (status signals)

- Holding Registers (40001–49999)

- Read/Write

- Parameters, counters, analog values

- Input Registers (30001–39999)

- Read-only

- Sensor measurements (temperature, pressure, energy)

Most industrial sensors use Input Registers or Holding Registers.

2. Common Data Formats

Register values may use different formats, including:

- INT16 (single register)

- UINT16

- INT32 / UINT32 (two registers)

- FLOAT32 (two registers, byte order required)

- BCD

To decode correctly, always check the device’s Modbus manual.

3. Addressing Differences: 0-Based vs 1-Based

Some manuals use:

- 0-based addressing (address 0 = 40001)

- 1-based addressing (address 1 = 40001)

If your readings look wrong, check the addressing mode.

4. Polling Frequency Matters

Polling too fast causes:

- Communication timeout

- CRC errors

- Bus overload

Typical stable polling rates:

- Sensors: 200–500 ms

- Meters: 1–2 seconds

- PLCs: depends on scan cycle

5. Always Validate Registers Before Deployment

Before integrating into your DAQ platform:

- Read a few registers

- Compare values with real measurements

- Confirm byte order for 32-bit data

This prevents incorrect data mapping in production.