RS485 is one of the most widely used communication standards in industrial data acquisition, but many field issues come from incorrect wiring. Proper wiring ensures stable communication, fewer CRC errors, and long-distance reliability.

1. Use the Correct RS485 Wiring Topology

RS485 requires a daisy-chain (bus) structure:

- Master → device 1 → device 2 → … → final device

- Avoid star wiring

- Avoid branching

Correct topology reduces signal reflections and data loss.

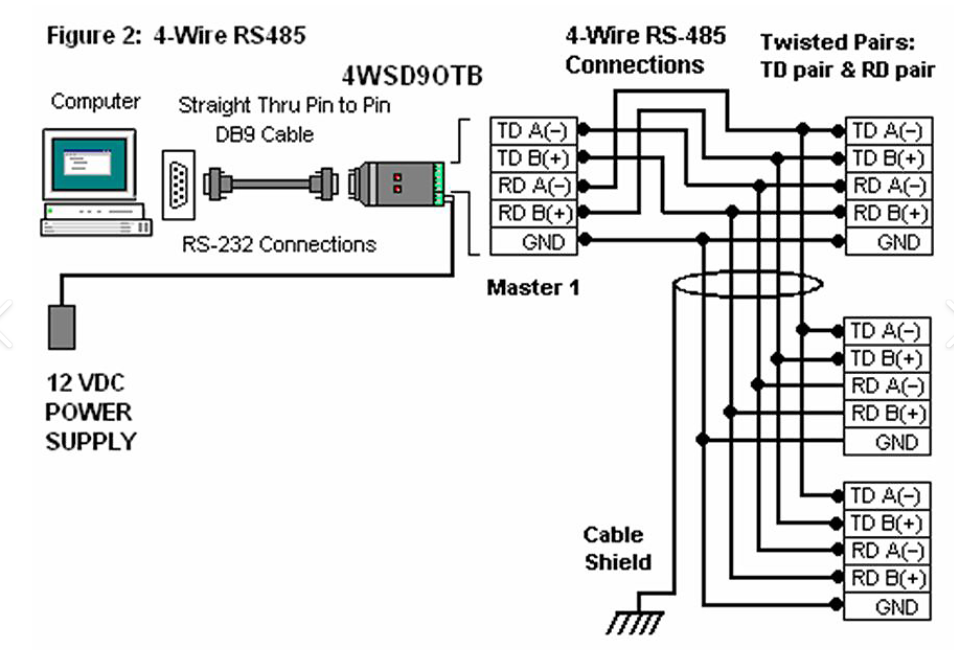

2. Proper A/B Line Connections

RS485 uses two differential lines:

- A (−)

- B (+)

Always confirm:

- A connects to A

- B connects to B

- Do not mix polarity

Reversed wiring is the most common cause of Modbus RTU communication failure.

3. Enable Termination Resistors

At both ends of the bus, add:

- 120Ω termination resistors

- Optional bias resistors for signal stability

Termination reduces noise and prevents reflection on long-distance cables.

4. Choose Industrial-Grade Shielded Cable

For stable communication:

- Use twisted-pair shielded cable

- Connect shield to ground on one side only

- Avoid routing near high-voltage power lines

Good cabling improves noise immunity in harsh factory environments.

5. Keep the Baud Rate Realistic

Longer distance → lower baud rate.

Typical stable settings:

- 9600 bps

- 19200 bps

- 38400 bps

Higher speed may cause CRC errors over long cables.

6. Test With a Modbus Scanner Before Deployment

Use a PC or gateway tool to validate:

- Slave address

- Baud rate

- Parity

- Register map

Always confirm communication before integrating into your DAQ system.