Industrial data acquisition (DAQ) is evolving rapidly as factories move toward automation, connectivity, and intelligence. Understanding future trends helps companies make long-term technology decisions.

1. From Data Collection to Intelligence

Traditional DAQ focused on:

- Reading sensors

- Logging data

Modern systems go further by adding:

- Real-time analytics

- Edge computing

- AI and machine learning

- Predictive insights

Data is no longer passive—it drives action.

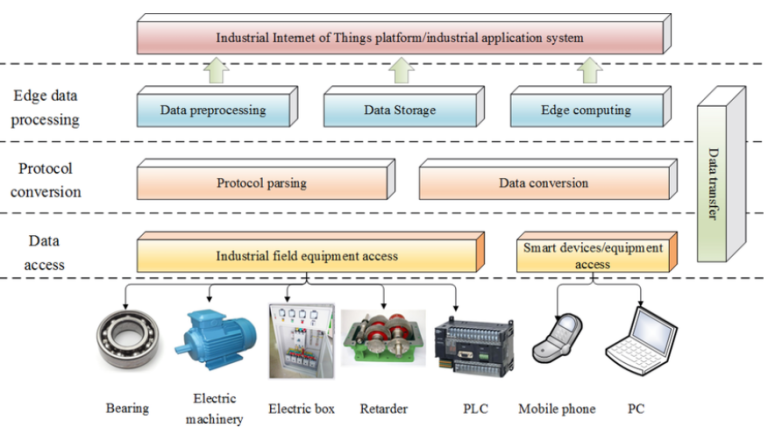

2. Edge + Cloud Hybrid Architectures

Future DAQ systems will:

- Process critical data at the edge

- Use the cloud for analytics and visualization

- Continue operating during network outages

This hybrid model balances performance, cost, and reliability.

3. Standardization and Open Integration

Open standards such as:

- Modbus

- OPC UA

- REST APIs

- MQTT

Will continue to dominate, enabling easier integration across vendors and platforms.

4. Cybersecurity by Design

Security will be embedded from the start:

- Zero-trust access models

- Encrypted communication

- Fine-grained user permissions

Secure DAQ systems are essential for connected factories.

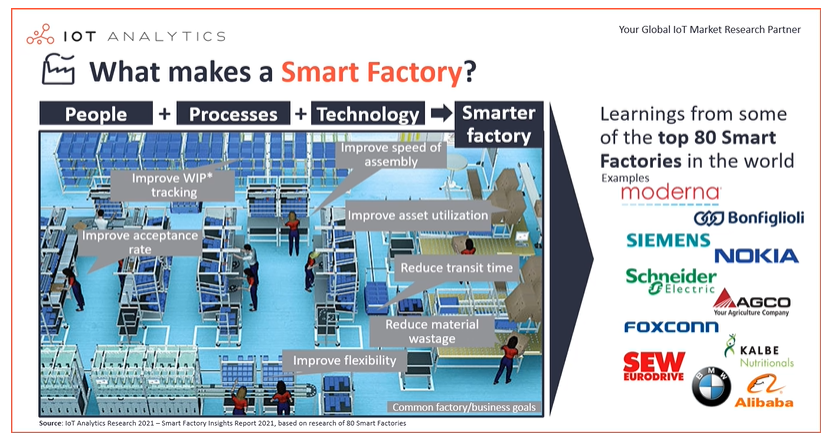

5. Data-Driven Competitive Advantage

Factories that fully leverage industrial data will:

- Reduce downtime and energy costs

- Improve product quality

- Scale operations efficiently

- Gain real-time operational visibility

Industrial data acquisition is the foundation of smart factories and digital transformation.