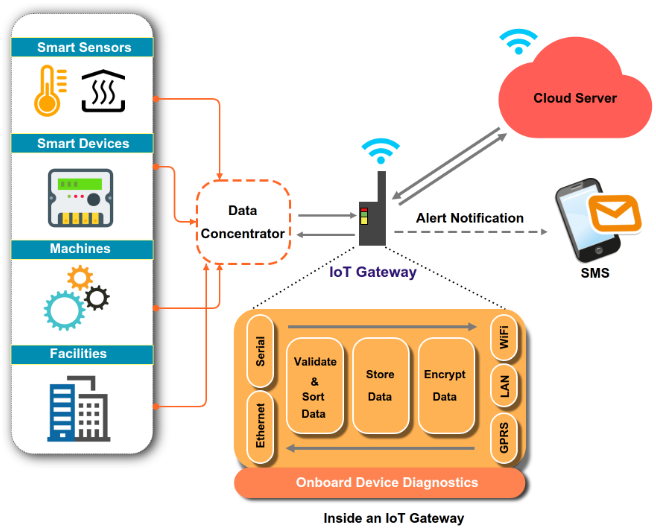

An Industrial IoT Gateway is the bridge that connects traditional factory equipment to web platforms, cloud systems, and modern analytics tools. It is one of the most important components in industrial digitalization.

Why Industrial IoT Gateways Matter

Most factory machines still use protocols such as:

- RS485

- Modbus RTU

- CAN

- 4–20mA / analog signals

These devices cannot connect directly to the internet.

An IoT gateway solves that problem by converting machine data into a format that IT systems can read.

What an Industrial IoT Gateway Does

A modern gateway provides several key functions:

1. Protocol Conversion

Convert industrial protocols into web-friendly formats:

- Modbus RTU ⇢ Modbus TCP

- RS485 ⇢ MQTT/HTTP/REST API

- PLC data ⇢ JSON

This enables seamless integration with dashboards and cloud services.

2. Real-Time Data Collection

It continuously reads data from sensors and machines:

- Temperature

- Vibration

- Current/voltage

- Production metrics

This ensures real-time visibility across the entire production line.

3. Edge Computing

Many gateways process data locally:

- Filtering

- Pre-processing

- Rule-based alarms

This reduces cloud traffic and improves response times.

4. Remote Monitoring and Control

Engineers can:

- View machine status online

- Set alarms and thresholds

- Remotely control certain devices

Ideal for multi-site factories and distributed systems.

Where IoT Gateways Are Used

- Manufacturing plants

- Smart buildings

- Energy management

- Water systems

- Industrial automation

- Equipment OEMs