Despite the rise of Ethernet and wireless technologies, Modbus RTU remains one of the most widely used industrial communication protocols today. Here’s why factories and OEMs still rely on it in 2025.

1. Simple and Reliable

Modbus RTU is extremely easy to implement:

- No complicated configuration

- Clear register-based structure

- Works on almost all PLCs, sensors, and controllers

This simplicity makes it ideal for industrial environments where stability matters most.

2. Low Cost and Long Distance

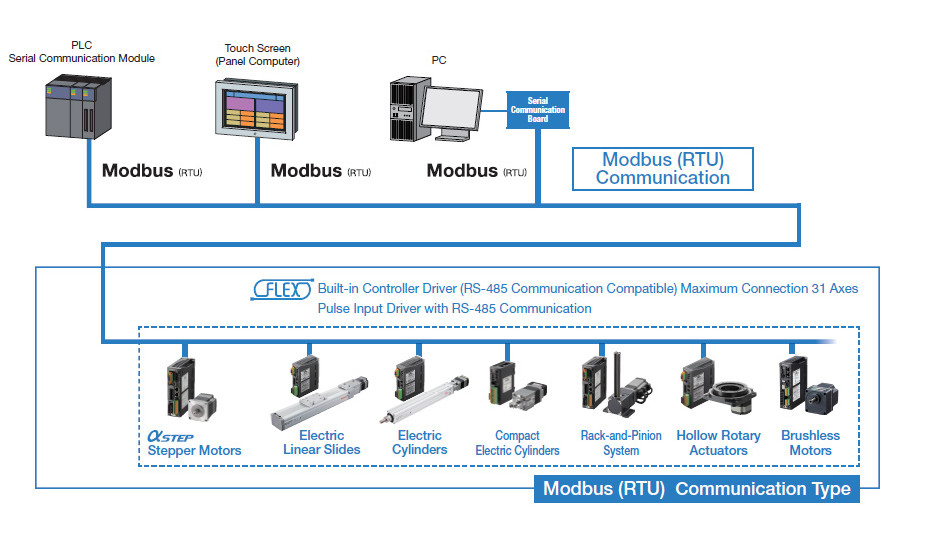

Because Modbus RTU runs on RS485, it supports:

- Up to 1200 meters communication distance

- Daisy-chain wiring

- Low installation cost

Perfect for factories with long production lines or distributed equipment.

3. Compatible With Old and New Machines

Modbus RTU is supported by:

- Legacy industrial equipment

- Modern IoT sensors

- Energy meters

- PLCs from brands like Siemens, Mitsubishi, Delta, Omron

This cross-generation compatibility keeps integration costs low.

4. Easy to Connect With Web Platforms

Modern DAQ systems and IIoT gateways can convert Modbus RTU data into:

- Dashboard visualizations

- Alarms and notifications

- APIs for cloud platforms

This makes Modbus RTU a perfect bridge between old industrial devices and modern web technology.