Industrial data acquisition architecture determines whether a system is reliable, scalable, and future-proof—or fragile, expensive, and impossible to extend.

Many industrial projects fail not because of sensors or software, but because the architecture was not designed for real-world industrial constraints.

This article explains how modern industrial data acquisition architectures are structured, what layers matter most, and how to design a system that scales from a single machine to an entire factory.

What Is Industrial Data Acquisition Architecture?

Industrial data acquisition architecture refers to the end-to-end system design that collects, transmits, processes, stores, and visualizes data from industrial equipment.

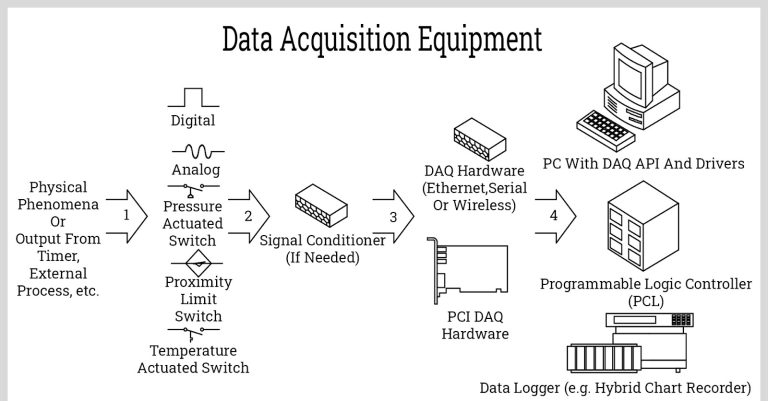

A complete architecture typically covers:

- Field devices and sensors

- Data acquisition hardware (DAQ, gateways, edge devices)

- Communication protocols

- Data processing and normalization

- Storage and visualization layers

A well-designed architecture ensures data accuracy, low latency, fault tolerance, and long-term scalability.

Why Architecture Matters More Than Hardware

In industrial environments:

- Devices are heterogeneous

- Protocols are fragmented

- Networks are unstable

- Expansion is inevitable

If architecture is not planned upfront:

- Adding new sensors becomes expensive

- Data formats become inconsistent

- Maintenance costs explode

- Integration with IT or cloud systems becomes painful

Architecture is what allows low-cost hardware to deliver high-value data systems.

The 5 Core Layers of Industrial Data Acquisition Architecture

1. Field Layer: Sensors and Machines

This layer includes:

- Temperature, pressure, vibration, current sensors

- PLCs, CNC machines, inverters, meters

- Cameras and vision devices

Key characteristics:

- Often vendor-specific

- Uses electrical signals or industrial buses

- Generates raw, unstructured data

At this stage, data is not yet meaningful—it is only signals.

2. Data Acquisition Layer: Gateways and DAQ Devices

This is where data acquisition actually happens.

Common components:

- Industrial DAQ modules

- Embedded gateways (ARM / x86)

- Edge controllers

Responsibilities:

- Read data from sensors and machines

- Convert signals to digital values

- Handle timing, sampling, and buffering

A good data acquisition layer should support:

- Multi-protocol access

- High reliability

- Local preprocessing

3. Communication Layer: Protocols and Transport

Industrial data acquisition relies on many protocols, such as:

- Modbus RTU / TCP

- OPC UA

- CAN / CANopen

- RS485 / RS232

- Ethernet / TCP-IP

Architecture best practices:

- Decouple protocol handling from business logic

- Use adapters or drivers per protocol

- Normalize data early

This layer determines how easily new devices can be integrated.

4. Processing Layer: Normalization and Logic

Raw industrial data must be transformed into usable information.

Typical processing tasks:

- Unit conversion

- Timestamp alignment

- Data validation

- Aggregation and filtering

- Alarm logic

This layer is often implemented at:

- Edge (for low latency)

- Server (for complex logic)

A modular processing layer allows rules to change without touching hardware.

5. Application Layer: Storage, Visualization, and APIs

This is where value is delivered.

Includes:

- Time-series databases

- Dashboards and monitoring systems

- Reporting tools

- REST or WebSocket APIs

Key architectural goals:

- Separate data storage from visualization

- Provide standardized APIs

- Enable integration with MES, ERP, or cloud platforms

This layer turns data acquisition into operational insight.

Centralized vs Edge-Based Architecture

Centralized Architecture

Characteristics:

- All data sent to a central server

- Simple initial deployment

- Higher network dependency

Best for:

- Small systems

- Stable networks

Limitations:

- Poor scalability

- High latency

- Single point of failure

Edge-Based Architecture (Recommended)

Characteristics:

- Local data processing at the edge

- Reduced network load

- Faster response

Benefits:

- Higher reliability

- Better scalability

- Lower long-term cost

Modern industrial data acquisition systems increasingly adopt edge-first architecture.

Common Architecture Mistakes in Industrial Data Acquisition

Avoid these common pitfalls:

- Tightly coupling hardware and software

- Hardcoding protocol logic

- Ignoring future expansion

- Treating all data as cloud-only

- No standard data model

These mistakes make systems brittle and expensive to evolve.

A Scalable Reference Architecture

A practical industrial data acquisition architecture should be:

- Modular – components can be replaced independently

- Protocol-agnostic – supports multiple devices

- Edge-capable – processes data close to the source

- API-driven – easy system integration

- Cost-efficient – avoids vendor lock-in

This approach enables gradual scaling from prototype to production.

How Architecture Supports Low-Cost Data Acquisition

With the right architecture:

- Commodity hardware becomes viable

- Open-source software can be leveraged

- Custom protocols are easier to implement

- AI and analytics can be added later

Architecture is what transforms data acquisition from a cost center into a platform.

Conclusion

Industrial data acquisition architecture is not just a technical detail—it is the foundation of every reliable industrial data system.

By separating layers, embracing edge processing, and designing for scalability, organizations can build data acquisition systems that grow with their operations instead of limiting them.

If you are planning an industrial data acquisition project, start with architecture—not hardware.