Industrial data acquisition is the foundation of modern smart factories, industrial automation systems, and equipment monitoring platforms.

Without reliable data acquisition, advanced analytics, dashboards, and AI models have no trustworthy input.

This article explains what industrial data acquisition is, how it works, the typical system architecture, common industrial protocols, and real-world use cases.

What Is Industrial Data Acquisition?

Industrial data acquisition is the process of collecting real-time data from industrial equipment—such as PLCs, sensors, meters, and machines—then transmitting, processing, and visualizing that data for monitoring, analysis, and decision-making.

A complete industrial data acquisition system typically includes:

- Data collection from field devices

- Protocol parsing and normalization

- Reliable data transmission through gateways

- Real-time visualization and historical storage

Modern factories increasingly rely on industrial data acquisition platforms to replace manual inspection, isolated controllers, and offline data logging.

Why Industrial Data Acquisition Is Critical in Modern Factories

Industrial environments demand accuracy, stability, and long-term reliability. Compared to consumer IoT, industrial data acquisition faces stricter requirements:

- Harsh electrical and physical environments

- Long-term continuous operation (24/7)

- Legacy equipment and mixed protocols

- High cost of data loss or system downtime

A professional industrial data acquisition solution ensures that raw device data can be trusted, audited, and reused across production, energy management, and maintenance systems.

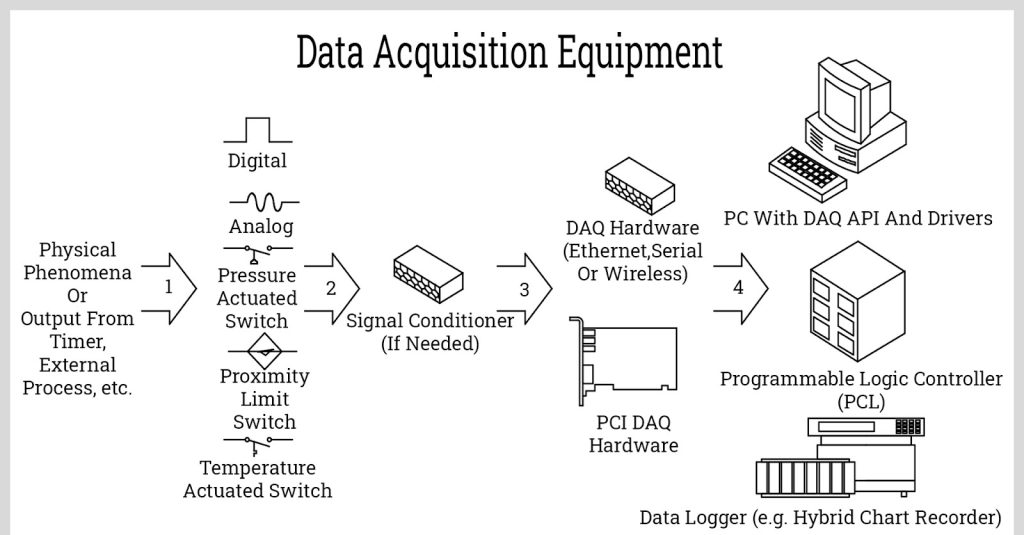

Industrial Data Acquisition Architecture

A standard industrial data acquisition architecture is typically layered, ensuring scalability and maintainability.

1. Device Layer

This layer includes physical equipment and sensors:

- PLCs and controllers

- Temperature, pressure, vibration, and flow sensors

- Energy meters

- Industrial cameras and vision systems

These devices generate raw operational data.

2. Data Acquisition Layer

The acquisition layer is responsible for communicating with devices using industrial protocols:

- Modbus RTU / Modbus TCP

- OPC UA

- RS485 / RS232 serial communication

- Custom TCP or proprietary protocols

At this stage, raw data is read, parsed, and converted into structured values.

3. Gateway & Edge Processing Layer

Industrial gateways play a key role in system stability:

- Protocol conversion and data normalization

- Edge preprocessing (filtering, aggregation, anomaly detection)

- Local buffering and offline data caching

- Secure communication handling

This layer reduces network load and improves system resilience.

Many modern factories deploy a dedicated industrial data acquisition platform at the gateway level to manage these tasks centrally.

4. Transport Layer

Collected data is transmitted using reliable and secure methods:

- MQTT or HTTP

- TLS encryption and certificate authentication

- Retry mechanisms and breakpoint resume

Stable data transmission is essential for distributed industrial systems.

5. Visualization & Application Layer

At the top layer, data becomes actionable:

- Web-based dashboards

- Real-time trend charts

- Alarm and event management

- Historical reports and analytics

Browser-based visualization allows engineers and managers to access data without installing dedicated client software.

Common Industrial Data Acquisition Protocols

Choosing the right protocol is critical for compatibility and performance.

Modbus RTU / TCP

One of the most widely used industrial protocols, especially for PLCs, meters, and sensors.

Simple, robust, and well-supported.

OPC UA

Designed for interoperability and structured data models.

Often used in complex automation systems and MES integration.

Serial Communication (RS485 / RS232)

Still common in legacy equipment and low-cost devices.

Requires careful handling of noise, distance, and timing.

Custom TCP Protocols

Used by equipment manufacturers with proprietary communication formats.

Require custom parsers and flexible acquisition software.

Typical Industrial Data Acquisition Use Cases

Industrial data acquisition is widely applied across industries:

- Factory production monitoring

Collect PLC operation data for real-time dashboards and alarms. - Energy management systems

Acquire data from power meters to analyze consumption and optimize costs. - Machine condition monitoring

Track vibration, temperature, and pressure for predictive maintenance. - Equipment manufacturer remote monitoring

Enable cloud-based monitoring for delivered machines. - Vision inspection systems

Upload inspection results and statistics from industrial cameras.

In all these scenarios, a scalable industrial data acquisition solution significantly reduces integration effort and long-term maintenance cost.

Industrial Data Acquisition vs Simple Data Logging

Many factories start with basic data loggers, but limitations quickly appear:

| Data Logger | Data Acquisition Platform |

|---|---|

| Local storage only | Centralized data management |

| Limited protocols | Multi-protocol support |

| No real-time visualization | Real-time dashboards and alarms |

| Hard to scale | Designed for expansion |

As systems grow, most factories migrate from standalone logging tools to a full industrial data acquisition platform.

Choosing an Industrial Data Acquisition Platform

When selecting a solution, consider:

- Supported industrial protocols

- Gateway and edge processing capabilities

- Data reliability and fault tolerance

- Web-based visualization features

- Deployment flexibility (local, edge, cloud)

A well-designed platform allows you to start small and scale as requirements evolve.

You can learn more about a practical implementation in our

industrial data acquisition platform for gateway-based data collection and web visualization.

Conclusion

Industrial data acquisition is the backbone of digital factories and modern automation systems.

By combining reliable device connectivity, robust gateways, secure data transmission, and web-based visualization, factories gain real-time visibility into operations and performance.

As industrial systems continue to grow in complexity, choosing the right industrial data acquisition architecture and platform becomes a strategic decision—not just a technical one.