Successful industrial data acquisition (DAQ) projects require more than hardware and software. A clear deployment checklist reduces risk, shortens implementation time, and ensures reliable operation.

1. Define Clear Objectives

Before deployment, identify:

- What data to collect

- Which machines or processes to monitor

- Required accuracy and sampling rate

- Business goals (downtime reduction, energy savings, OEE)

Clear goals guide system design and budgeting.

2. Select the Right Sensors and Interfaces

Confirm:

- Measurement range and accuracy

- Output type (RS485, Modbus, analog, Ethernet)

- Environmental ratings (IP, temperature, vibration)

- Compatibility with DAQ hardware

Proper selection avoids costly rework.

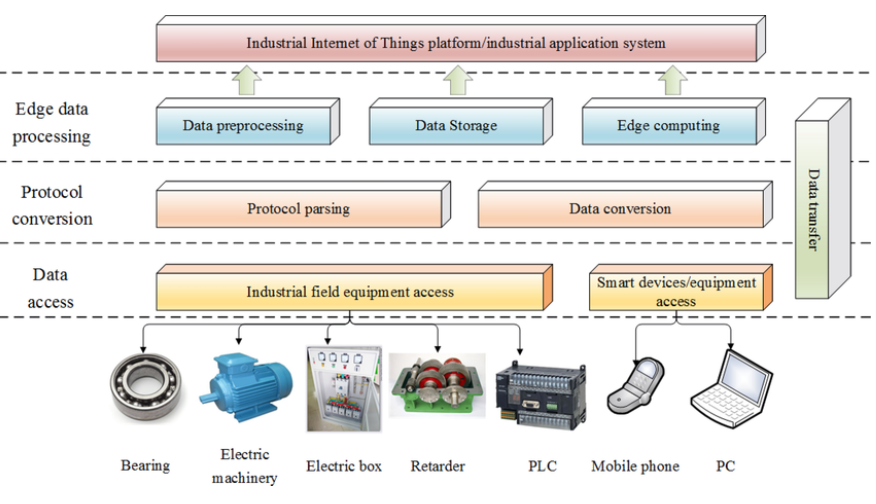

3. Plan Network and System Architecture

- RS485 wiring topology and termination

- Ethernet network layout

- Edge vs cloud processing strategy

- Data storage and retention policy

Good planning ensures scalability and performance.

4. Configure Data Collection and Alarms

- Polling intervals

- Register mapping

- Thresholds and alarm priorities

- Notification methods

Test all configurations before going live.

5. Address Security and Reliability

- User roles and access control

- Secure communication (VPN, HTTPS)

- Backup and disaster recovery

- Documentation and training

A disciplined approach ensures long-term system stability.