Before investing in an industrial data acquisition (DAQ) system, decision-makers want to understand the return on investment (ROI). A clear ROI model helps justify digitalization projects and prioritize deployments.

1. What Drives ROI in Industrial DAQ?

Industrial DAQ delivers value by:

- Reducing unplanned downtime

- Lowering maintenance costs

- Improving energy efficiency

- Increasing production output

- Reducing manual data collection

These benefits translate directly into cost savings and revenue gains.

2. Key Cost Components

Typical DAQ project costs include:

- Sensors and meters

- DAQ hardware or IoT gateways

- Network and installation

- Software licenses or cloud services

- Integration and maintenance

Understanding total cost of ownership (TCO) is essential for accurate ROI.

3. Quantifying the Benefits

Common measurable gains:

- Downtime reduction (%) × hourly production loss

- Energy savings (kWh) × energy price

- Maintenance labor reduction

- Scrap and defect rate reduction

Even small improvements often produce significant annual savings.

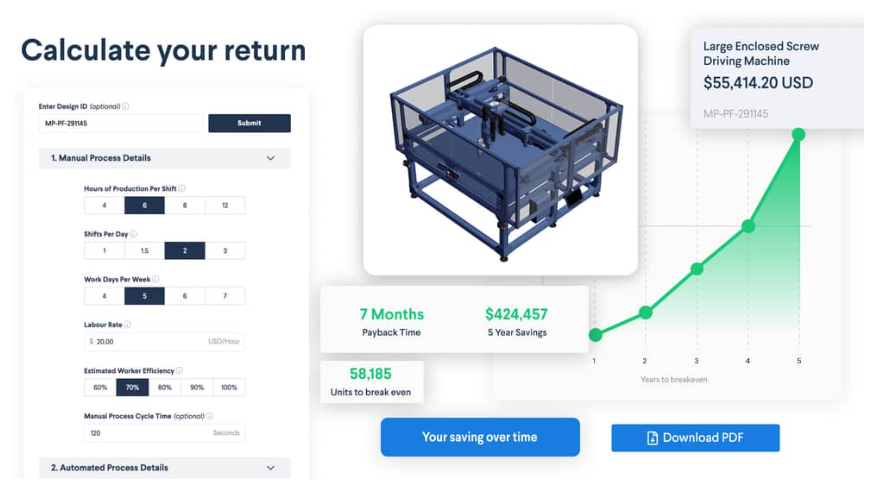

4. Payback Period Expectations

In many industrial projects:

- Payback period: 6–18 months

- Energy monitoring projects: often < 12 months

- Predictive maintenance projects: high long-term ROI

This makes DAQ one of the fastest-return digital investments.

5. Why Data-Driven ROI Matters

Clear ROI metrics:

- Accelerate management approval

- Support phased rollouts

- Align IT and OT teams

- Ensure long-term project success

Industrial data acquisition is not just a technical upgrade—it is a measurable business investment.