Remote operations enable engineers and managers to monitor, control, and maintain industrial equipment without being on-site. Combined with DAQ systems and web platforms, remote operations improve efficiency and reduce costs.

1. What Is Remote Industrial Operation?

Remote operations use connected sensors, gateways, and dashboards to:

- Monitor machine status

- Control equipment parameters

- Receive real-time alerts

- Access historical performance data

This allows centralized management across multiple factories or production lines.

2. Benefits of Remote Operations

- Faster Response: Issues are detected and resolved immediately

- Reduced Travel Costs: Engineers don’t need to be on-site

- Improved Maintenance: Early fault detection prevents unplanned downtime

- Better Resource Allocation: One team can manage multiple sites

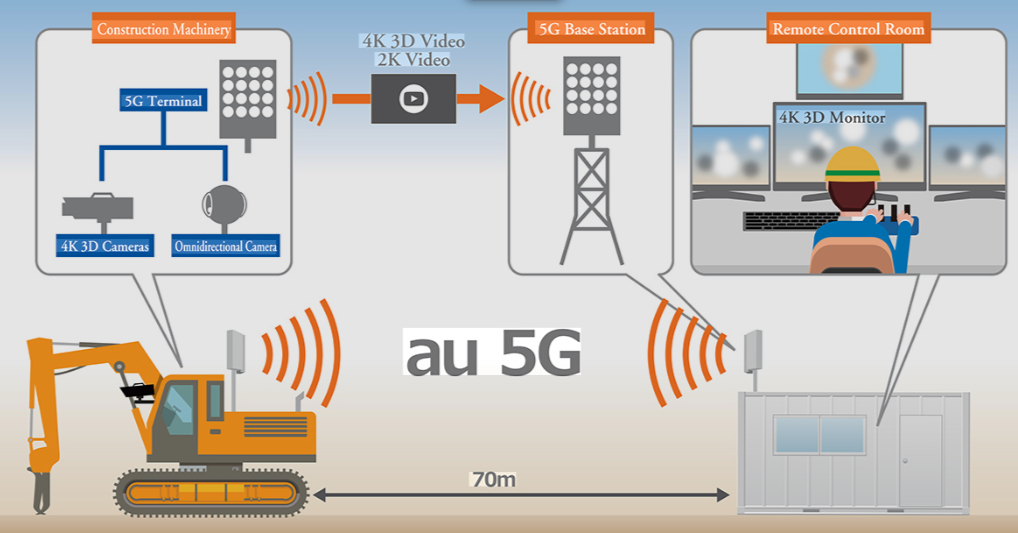

3. How It Works

- Sensors and DAQ hardware collect machine data

- Edge devices process and send critical data to the cloud

- Web dashboards display real-time metrics

- Alerts are sent via email, SMS, or mobile apps

- Operators can adjust machine settings remotely (if allowed)

4. Best Practices

- Secure all remote connections with VPN or HTTPS

- Define user roles and permissions

- Ensure reliable network redundancy

- Log all remote operations for auditing and troubleshooting

Remote operations turn industrial data into actionable control, allowing smarter, more responsive factories.